CORONA

TREATMENT

for Printing and Coupling

Printing and Coupling

TCU20-M4

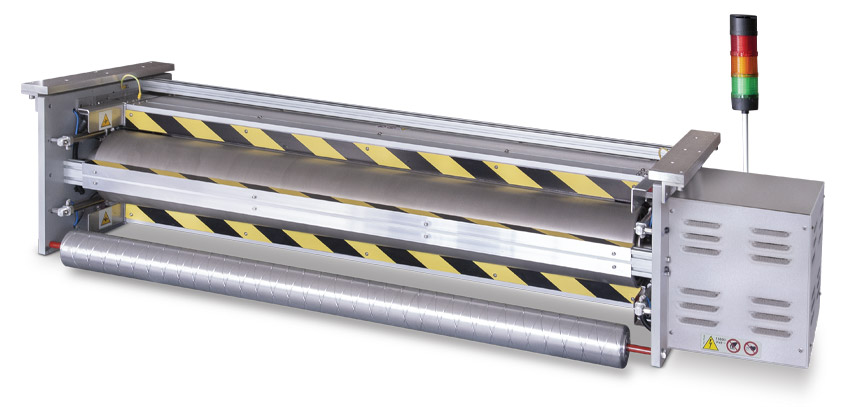

TCB20-M4

TCU20-M4 SERIES: Corona Treatments for Printing and Coupling

One-side corona refreshment systems for increasing the wettability of metallised and flexible insulation films on high speed printing and laminating machines (up to 550 m/min).

Each system consists of a TCU20-M4 one-side discharge unit, a GET electronic power generator, and an ozone extraction system.

The discharge station is designed to simplify all the most common use and maintenance operations: material insertion, air-gap calibration, and electrode cleaning.

Electrodes:

• 4 ceramic Cason electrodes with a large discharge surface and a custom design that aids cooling and ensures a long service life.

• Segregated in protective boxes with pneumatic opening-closing mechanisms for easy material insertion.

Treatment roller:

• Statically and dynamically balanced

• Coated with a special custom coating by Cason (for metallised materials)

• Predisposed for motorisation

Ozone suction system:

• Designed to keep the discharge electrodes well cooled and very clean.

Safety, sensors, and signals:

• The emergency stops, mobile guards, and electrode boxes are monitored by dual channel safety switches.

• Dedicated sensors for controlling the rotation of the treatment rollers and the extraction flow.

• Signals: Acoustic buzzer, 3-colour light column.

Main construction materials:

• Stainless steel and aluminium.

TCU20-M4

| TECHNICAL SPECIFICATIONS | |

| Focus | High-performance and versatile, high-speed refreshment |

| Application | Printing / lamination |

| Materials | Metallised and Flexible insulating materials |

| Sides | 1 |

| Range | Up to 1800 mm |

| Electrode Bars | 4, Ceramic, non-sectionable |

| Treatment rollers | 1, ø 200 mm, ceramic coating, predisposed for motorisation |

| Optionals | 1) Horizontal and Vertical Version 2) Inlet and outlet path rolls by design 3) Fixing plates by design 4) Motorisation |

TCB20-M4

| TECHNICAL SPECIFICATIONS | |

| Focus | High-performance and versatile, high-speed refreshment |

| Application | Print / triplex lamination |

| Materials | Metallised and Flexible insulating materials |

| Sides | 2 |

| Range | Up to 1800 mm |

| Electrode Bars | 4 per side, Ceramic, non-sectionable |

| Treatment rollers | 2, ø 200 mm, ceramic coating, predisposed for motorisation |

| Guide rollers | intake (spiralled) + outlet, natural aluminium |